Capabilities

Tunnel and Model DAQ, Pressure Transducers and Thermocouples

Data is acquired using a DAS consisting of National Instruments hardware and a combination of National Instruments and MATLAB software.

T5

Typically, a model is instrumented with up to eighty thermocouples to analyze the heat flux, sampled at 200kHz. The shock tunnel itself is instrumented with the following: two LVDT's measuring displacement of the CT and the 2R, two transducers in front of the main diaphragm to measure burst pressure, four transducers located at intervals along the ST to measure shock speed, and two transducers at the end of the ST to measure reservoir pressure.

Ludwieg Tube

Models can be instrumented with up to 5 piezoelectric pressure transducers, and injection experiments which use an Omega flow meter to measure mass flow rate. The tunnel is instrumented with Kulite piezoresistive pressure transducers both at the reservoir and along the nozzle to calculate freestream static pressure and to ensure proper tunnel operation. There is also an Omega type K thermocouple at the reservoir to measure static temperature. Experiments are currently underway using pressure- and temperature-sensitive paints.

HET

PCB piezoelectric pressure transducers are used on the model.

Flow Visualization

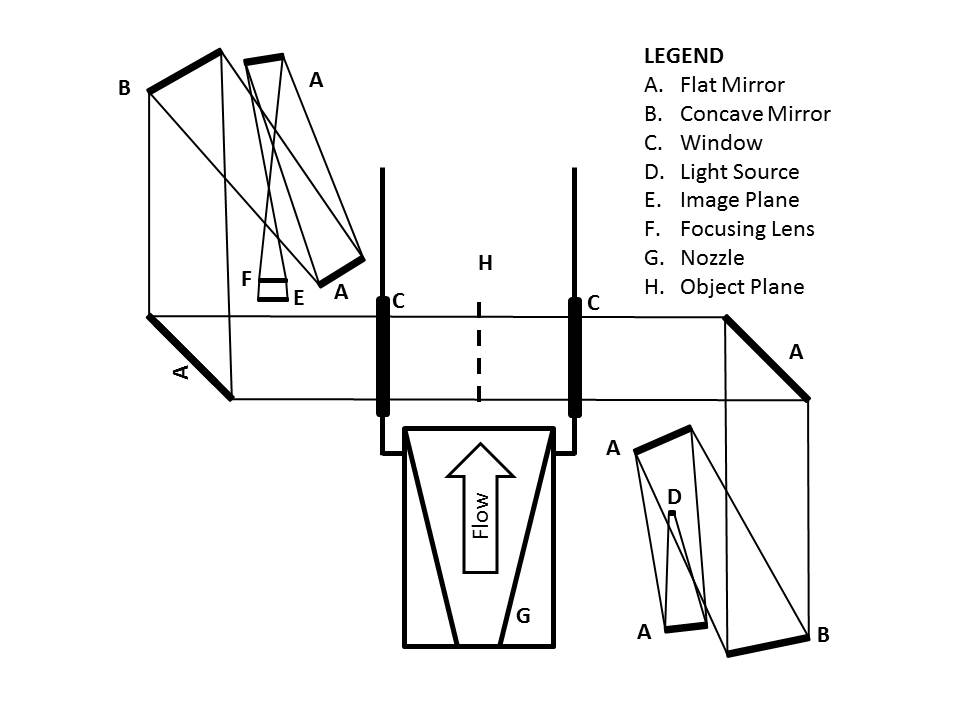

Both conventional and focused schlieren setups have been used in T5, although conventional schlieren is used most often. Conventional Z-type schlieren setups are used with both the Ludwieg tube and the HET. A powerful 2.8 A Cree X-Lamp LED is used as a continuous white light source for long-exposure images in the Ludwieg tube. A pulsed diode-laser source is used for ultra-short exposure time images with exposure times as short as 20 ns with the Ludwieg tube and T5 facilities. Phantom v710 and Shimadzu HPV-X high-speed cameras are used for high speed imaging.

Conventional Schlieren Setup

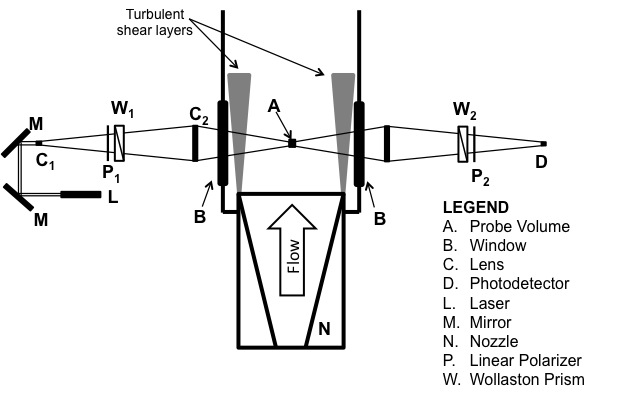

Focused Laser Differential Interferometer

A Focused Laser Differential Interferometer (FLDI) was developed by Parziale to measure point density fluctuations in the boundary layer around the test article. It is extremely sensitive and detected Mack mode frequencies in transitional boundary layers. For more information, see Parziale's thesis.

FLDI Schematic

T5 Established Run Conditions

Variation on shock tunnel input parameters throughout the duration that T5 has been operational has led to established run conditions. That is, T5 exhibits reproducible free-stream conditions. These conditions will be posted soon.

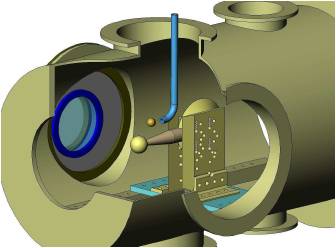

Computer Aided Engineering Tools

A suite of computer aided engineering tools is available to the research staff at T5 through appropriate licensing. These CAE tools aid the staff in efficiently producing an effective experiment. Some examples are solid modeling to prepare a sting for a test article (see below, image from Lawrence's thesis) and computational fluids codes to estimate the conditions in the shock tunnel, nozzle throat and nozzle exit.